Hi! 👋, my name is Shashank and I am a mechanical engineer,

developing intelligent solutions that optimize performance, enhance user experience, and drive sustainable innovation.

Design 🦾

Each project is unique. Here are some of my works.

SOLIDWORKS, LOTUS, ADAMS CAR, ANSYS

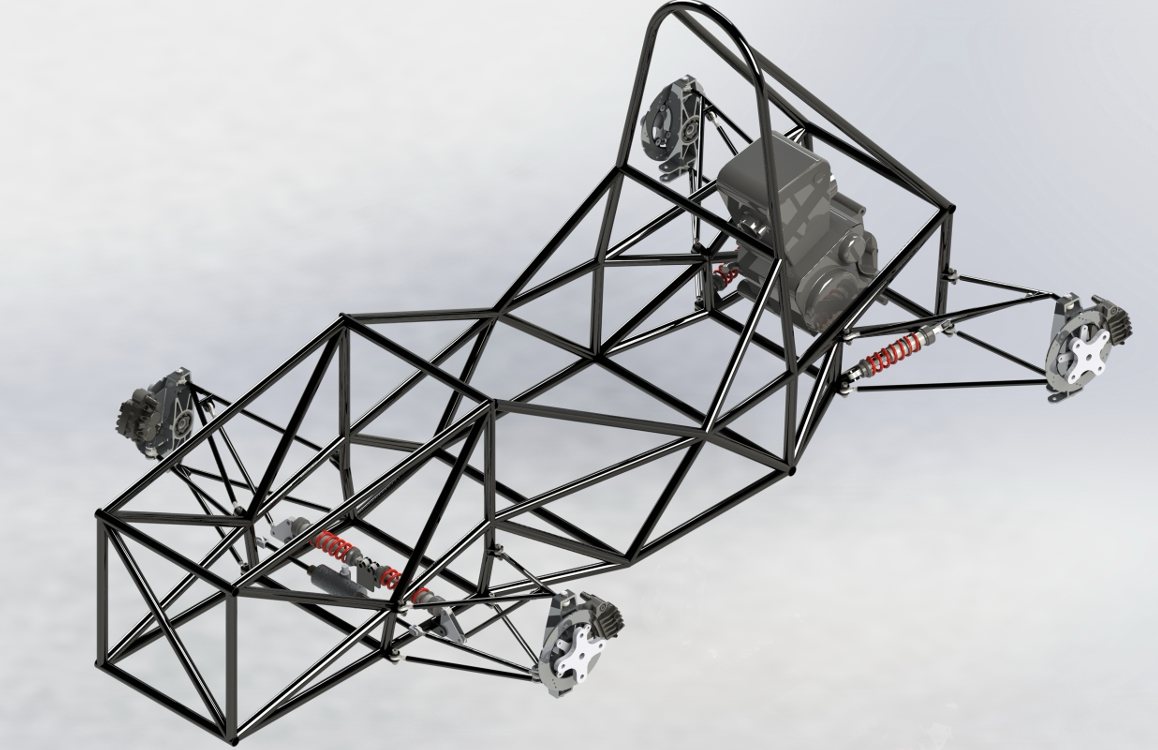

Formula

SAE 2019

Designed and fabricated a single-seat formula race car under SAEINDIA regulations, serving as core design engineer for steering, rims, chassis, and seat components using SolidWorks and CATIA with GD&T. Successfully passed technical inspections and raced at BIC, ranking 36th nationally. Applied FEA to reduce weight by 83 kg.

SOLIDWORKS, LOTUS, ADAMS CAR, ANSYS

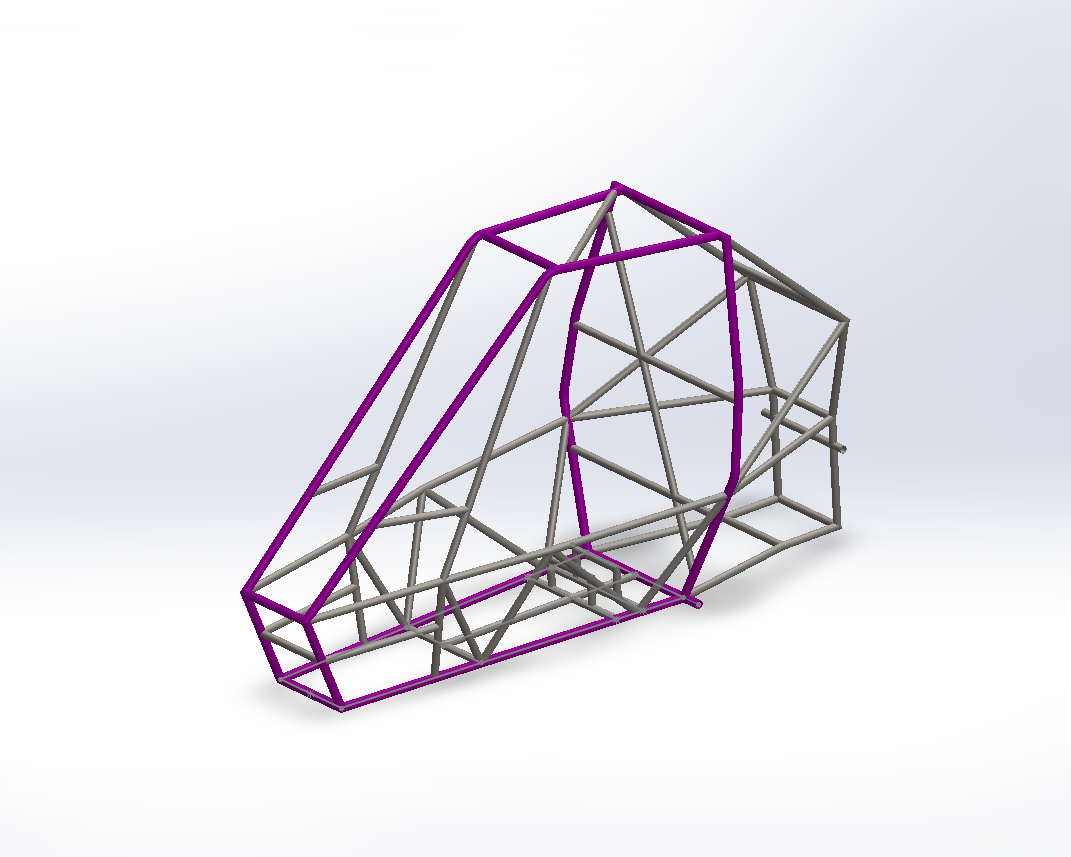

SAE

Baja 2018

Spearheaded prototyping for a BAJA SAE vehicle focusing on chassis and powertrain systems. Used modular fabrication for rapid iteration, calculated CVT torque-speed match and optimized gear ratios. Achieved 20% drivetrain efficiency increase, 12 kg weight reduction, and became first team from my college to complete endurance event.

SOLIDWORKS, LOTUS, ADAMS CAR, ANSYS

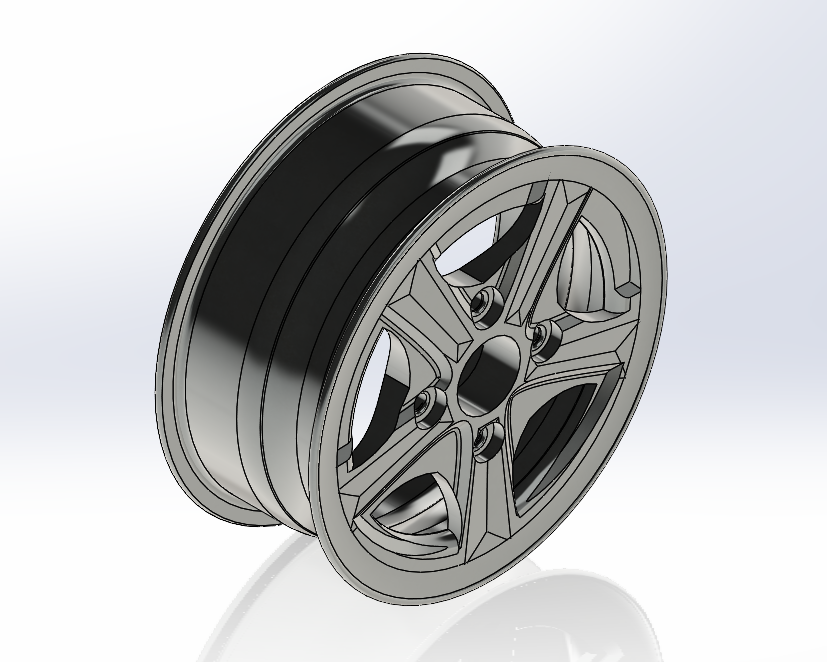

Wheel Rim

DESIGN

Created a 15-inch alloy wheel rim for a Formula SAE vehicle by accurately modeling from real-world specs in SolidWorks, incorporating bolt patterns, ventilation, and offsets. Performed stress and fatigue analysis using ANSYS, achieving safety factors > 1.5 and dimensional tolerance under 0.5 mm for simulation and assembly clearance.

SOLIDWORKS, ANSYS

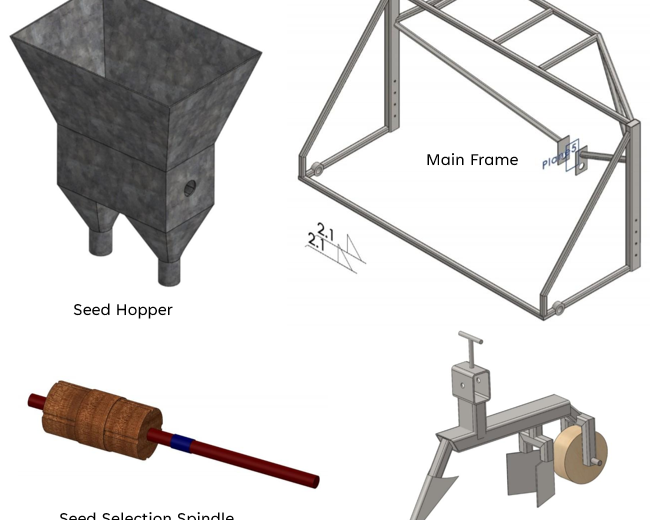

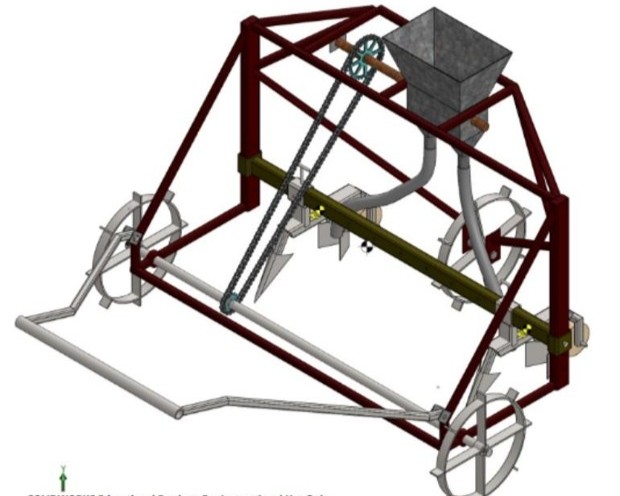

Seeding Mechanism

Design

Designed and analyzed a low-cost, manually operated seeding mechanism to optimize seed spacing and reduce labor requirements for small-scale farms in rural India. Modeled a rotating-disc seed metering system in SolidWorks for uniform seed delivery with minimal clogging, tailored for crops like maize and mustard. Performed static structural analysis to ensure frame strength under soil resistance and operator load, validating a safety factor above 2.5. A complete CAD assembly with manufacturing drawings was prepared, though fabrication was halted due to COVID-related restrictions.

Analysis 🚁

CREO, ADAMS CAR

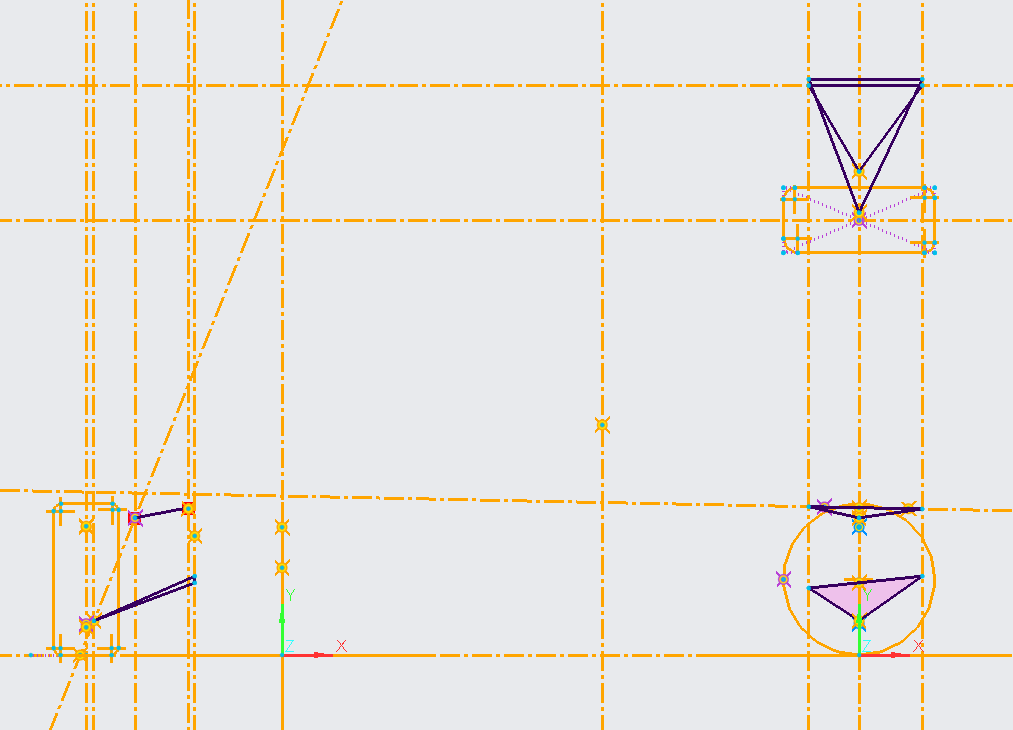

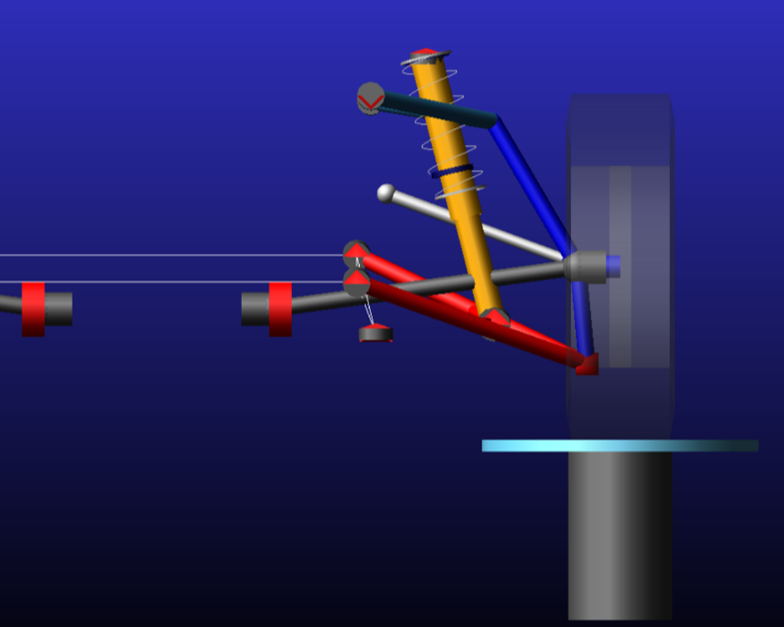

Double Wishbone

Suspension Design

Engineered a high-performance double wishbone suspension system for a formula-style race car using Creo and ADAMS Car. Tuned critical geometric parameters like track width, camber gain, and roll center height. Simulations showed a 12% reduction in body roll and improved tire contact consistency by 15%, with less than 1.5 mm bump steer—resulting in a digitally validated suspension model ready for prototyping.

SOLIDWORKS, ANSYS

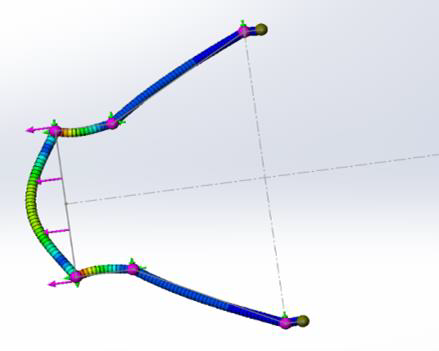

Handle & Furrow

Statics Load Analysis

Conducted structural analysis on a manually operated furrow blade and handle system for agricultural use. Designed the model in SolidWorks with realistic pulling and soil resistance loads (~300 N pull and 150 N soil contact). Static simulation yielded a minimum safety factor of 2.4. Refined the blade tip geometry to reduce peak stress by 18%, ensuring long-term usability under field conditions.

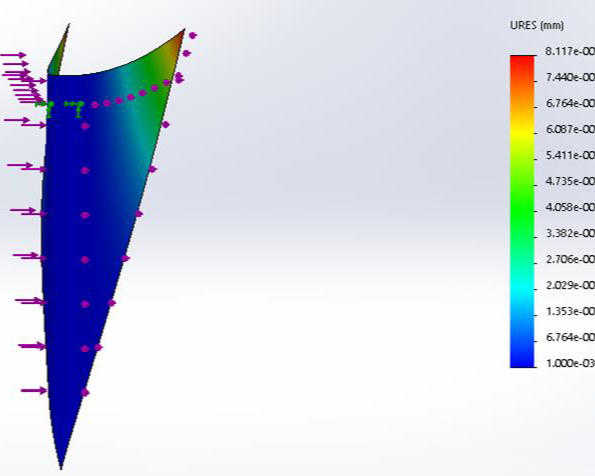

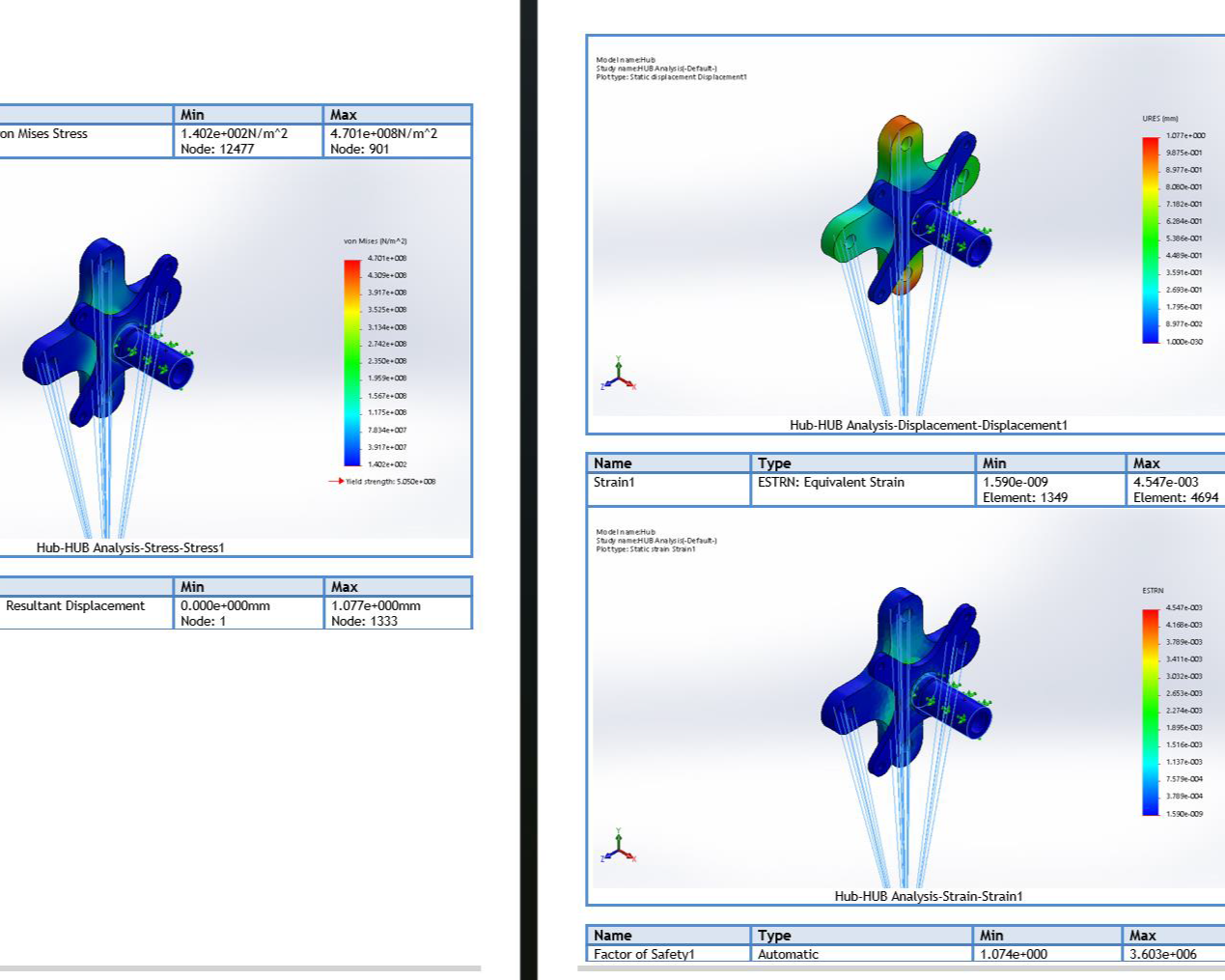

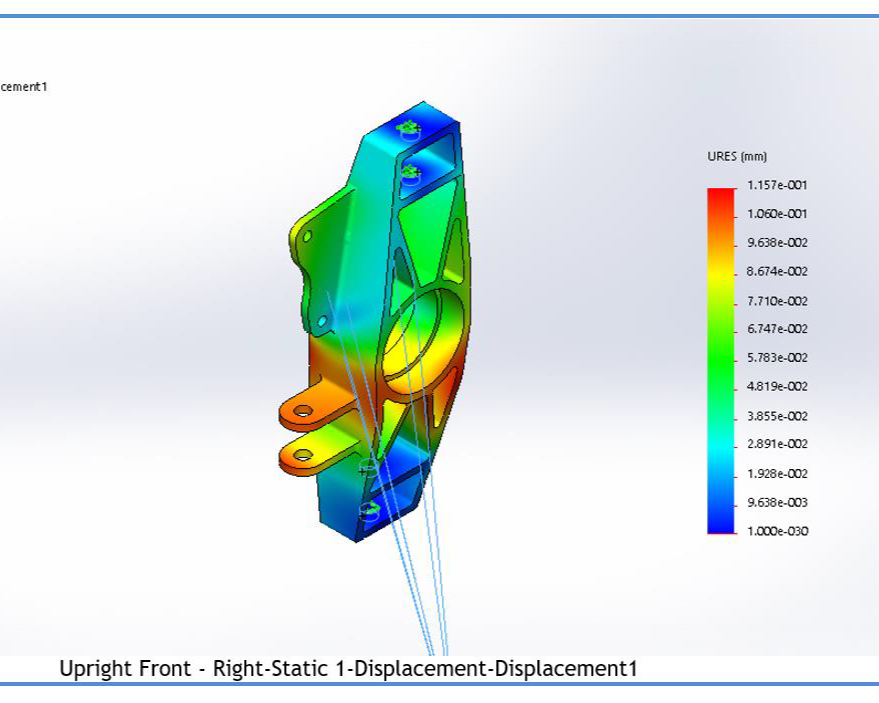

CATIA V5, SOLIDWORKS, ANSYS

Wheel Hub & Upright

Static Load Analysis

Performed static structural analysis of the front wheel hub and upright assemblies for an FSAE vehicle using CATIA V5 and SolidWorks Simulation. Applied racing boundary conditions such as 2g cornering, 1.5g braking, and 1000 N vertical loads. Verified safety through Von Mises stress distribution and ensured structural integrity with a factor of safety of 2.1. The final design was cleared for CNC machining and integration into the suspension system.

Robotics 🛰️

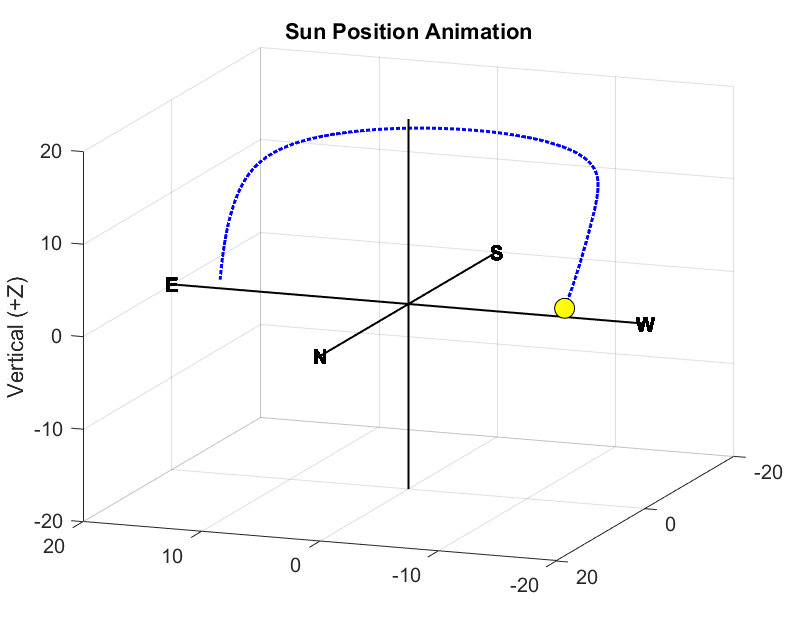

MATLAB, SIMULINK, C/C++

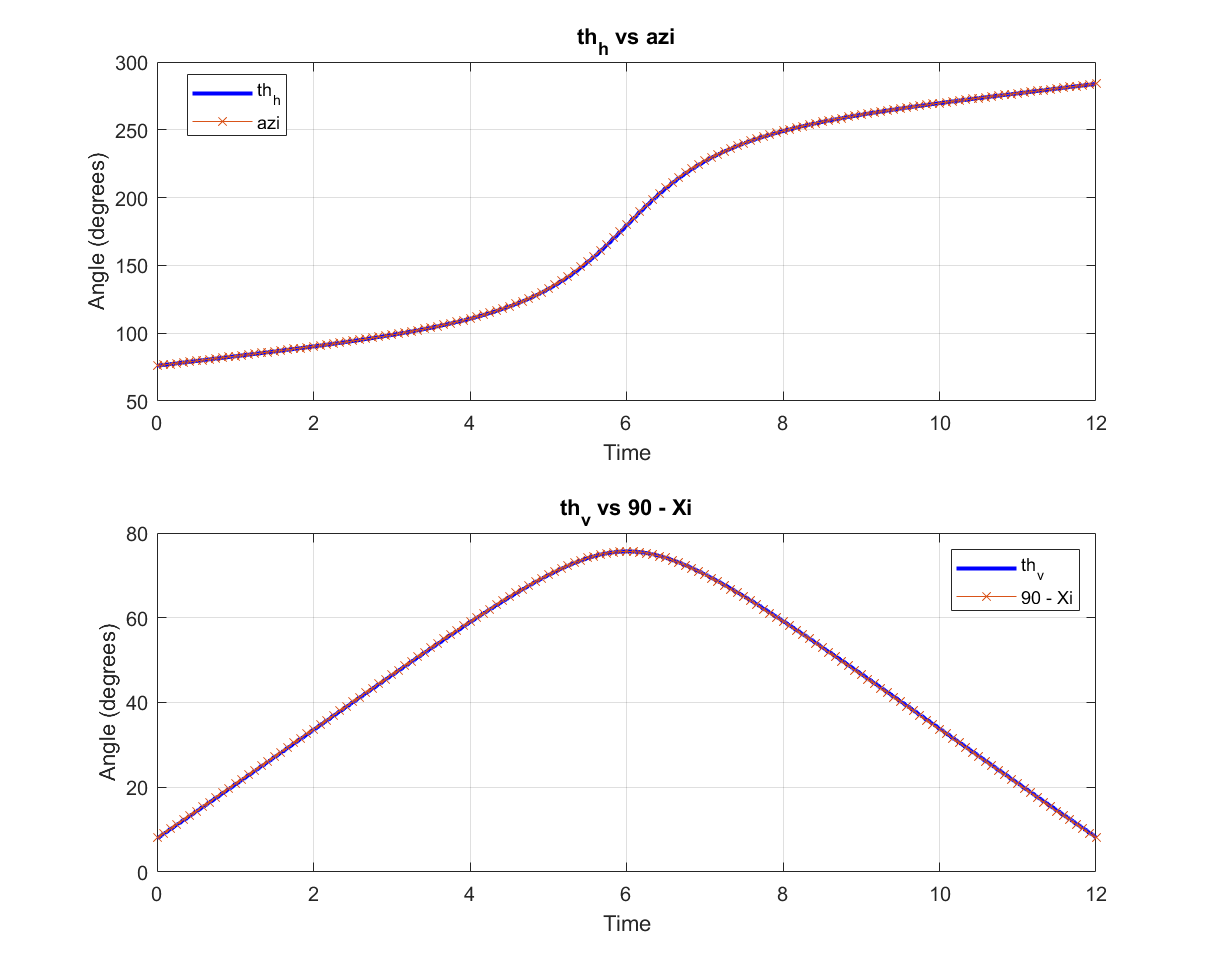

Optimal Control

of a Solar Panel

Developed and simulated an optimal control system for a dual-axis solar tracker in MATLAB. Modeled the tracker as a nonlinear second-order plant and applied optimal feedback control to align panel angles with solar trajectory. Improved simulated solar energy capture by 32% over static panels while maintaining robustness to actuator delays and cloud-induced disturbances.

MATLAB, SIMULINK, C/C++, LATEX

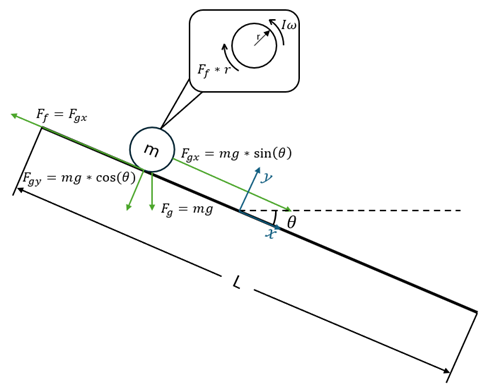

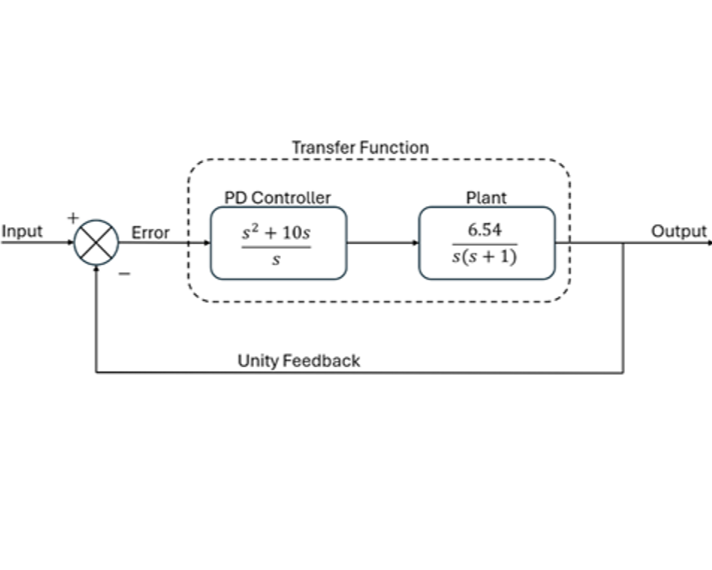

Ball on Plate

Control System

Simulated a closed-loop control system to balance a ball on a flat plate using MATLAB. Implemented a PD controller for real-time stabilization in two axes. The system successfully restored ball position from a 10 cm displacement in under 1 second and maintained steady tracking within ±1 cm, even under added random disturbances.

MATLAB, SIMULINK, C/C++

Surveillance

Quadcopter Design

Designed and built a quadcopter from scratch, first with an Arduino based flight controller then migrated to a KK2.1.5 board. Implemented PID attitude and altitude hold with IMU fusion and MATLAB Simulink tuning; recovered from a 10 cm offset in under 1 s and held position within ±1 cm and attitude within ±2 degrees under gust and step disturbances.

Technologies 🚀

What Technologies I Used